|

|

|

||||

|---|---|---|---|---|

Team Magic E4RS III Concept:

|

|

|||

|

||||

|

|

|||

Designing the Team Magic E4RS III:I never been so involved in the design of an RC car; and I'm particularly proud to have made the connection between various team drivers and the Team Magic own designers. The E4RS III is the result of a long work of study, drawing and numerous discussions with the Team Magic drivers of whom I'm in charge of here in Europe. Each of them had the possibility to express their opinion, to suggest ideas and to talk about their experience. I thank all the drivers for their precious help, as well as for their results and involvement. The E4RS III can be considered as a completely new car (even if some aspects come from the E4RS II EVO) because considerable changes were brought forward, in particular in terms of the bulkheads and arm mount; but that's not all. Overall, more than half of the car parts are new. On this matter, I would thank Team magic who imposed absolutely no constraints; I could have made the choice of not keeping any parts from any of the previous cars - which is extremely rare for manufacturers, who try to avoid having to create new moulds or simply to draw new parts. As a result, we had carte blanche; proof that the collaboration HRC / Team Magic is based on confidence and trust, and that my work on the E4RS 09, E4RS II, E4RS II EVO, E4JS and E4JR was successful. Then, if we had carte blanche, why not change everything? Because we could not risk putting nearly six years of development to waste. By starting of a plain sheet, there is surely a big risk of making errors, or rather of creating something imperfect. There, we know what works on the E4RS II EVO, we know the imperfections which we want to improve, and the qualities which we do not want to lose. I therefore think that the E4RS III is much better accomplished than if we had started at 0. Lionel Troyon - co-developer of the E4RS III |

|

|||

|

||||

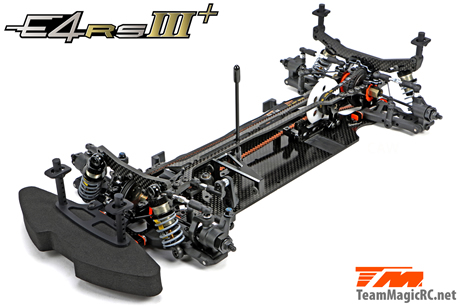

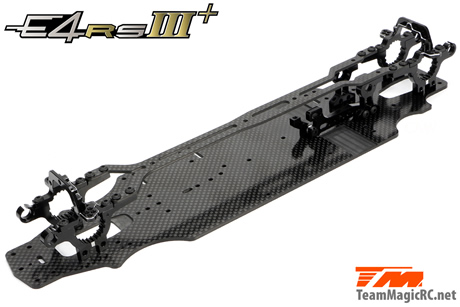

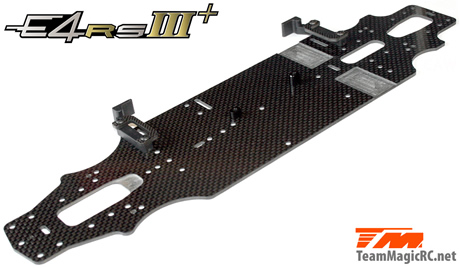

+++ Chassis:Entirely satisfied by the chassis shape of the E4RS III, we just modified his thickness and the FF arm mount position for the E4RS III+. Indeed, after several months of tests, we observed the flex obtained with the 2.5mm is a little bit more versatile, and suits better to the most of the tracks. The symmetric flex concept is obviously maintained, because it's a key aspect of the E4RS II and E4RS III series's excellent handling capabilities. |

|

|||

Upper deck:The E4RS III and III+ upper deck, made of High Grade 2.0mm graphite, is new. In comparison to the E4RS II EVO, we refined the rear area and the double steering mounting holes have been replaced by a central hole, allowing to finer tune the flex in this area. We also modified the mounting height of the upper deck to the bulkheads, in order to insure a better control of the flex movements. |

|

|||

Flex optimisation:The overall flex of the chassis as well as its control has been updated. The more compact bulkheads and the new steering system provide a better flex distribution on a wider area. The upper deck, 2mm higher, as well as the multiple fixation points allows for a better flex management. |

|

|||

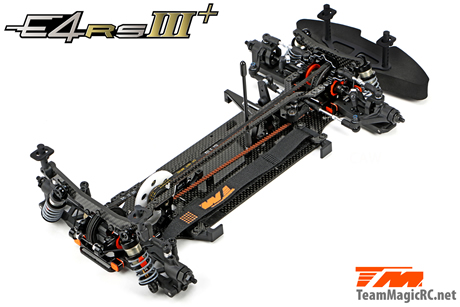

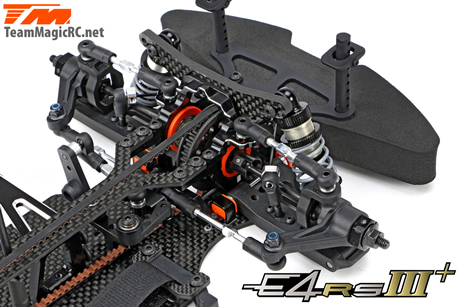

Lateral adjustment of the motor position:We decided to keep the E4RS II EVO architecture of the motor and central layshaft mounts, with the exclusive lateral motor position adjustment. Team Magic is the only manufacturer of the market to propose this adjustment, since almost two years. |

|

|||

+++ Motor mount:To allow a larger range of possible settings of the gear ratio, we widened the motor mount mounting holes. This allows the use large pinions gears without having to use smaller spur gears. For the E4RS III+, we decided to black anodize this part. Our motor mount keeps its original design which allows for an extremely secure motor fixation. |

|

|||

Central layshaft mount:In order to lighten the E4RS III and III+, the central layshaft mounts have been modified. We also increased the height of the middle layshaft, to allow the use of larger spur gears and to increase the ratio range. |

|

|||

Lower bulkheads:The lower bulkheads of the E4RS III and III+ are completely new. They are lighter than its previous counterparts; they allow for a finer belt tension setting and set the new upper deck height. They also directly support the anti-roll bars via a ball bearing system which was only an option for the E4RS II and E4RS II EVO. Note that these parts are the same on front and rear, to minimise the number of spare parts. |

|

|||

+++ Upper bulkheads:The upper bulkheads of the E4RS III are also new, to optimise the upper turnbuckle mounting holes and therefore the roll centre adjustments. We also modified them to better fit the new ultra rigid shock towers. On the E4RS III+, these bulkheads have also been reinforced. As with the lower bulkheads, the upper ones are also the same on the front and rear to minimise the spare parts. |

|

|||

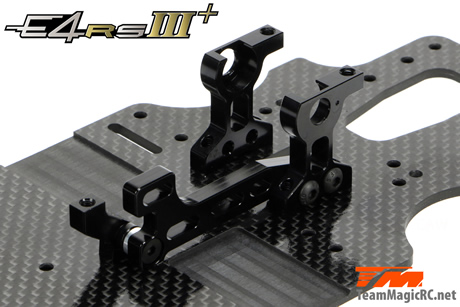

+++ Suspension arm holders:This is the modification which asked the most work during the design phase E4RS III and III +. To avoid to require a multitude of different arm mounts, to adjust the width and the arm angles, we choose to use a system of inserts allowing a ultra fine and precise setting *LT. On the E4RS III+, the inserts have been renforced, and the pivot balls are now machined in hard threated aluminum. A new one-piece FR arm mount allows now a better front flex control. |

|

|||

|

|

|||

+++ Suspension arm holder inserts:To adjust very finely the arm position on the lateral plan, we created arm holder inserts allowing a variation of 0.2mm. Three inserts allows 5 positions:

The inserts of E4RS III+ are the new reinforced ones. |

|

|||

+++ Aluminum pivot balls:To strengthen this tender spot and guarantee a perfect liberty of movements, the arm pivot balls of the E4RS III + are now on aluminum. This provides lightness, liberty and solidity to the assembly. |

|

|||

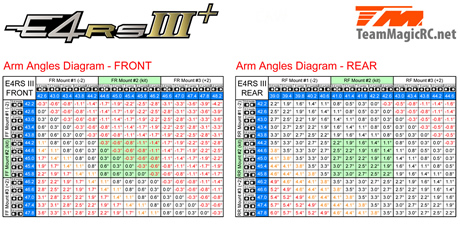

Suspension arms angles:This is definitely the most worked aspect of the E4RS III and III+. For this, we not only wanted to keep as similar as the E4RS II EVO, which provided an excellent base, but also to offer the finest settings available on the market. For that purpose, we created 3 RF/FR mounts and 3 FF/RR mounts. Please note that the supports are the same for font and rear, in order to minimize the number of parts. |

|

|||

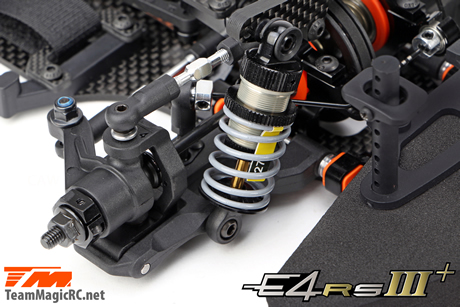

Hard coated suspension shafts:The suspension shafts are hard coated polished steel, in order to ensure perfect alignment and movements without any hard points. The outer shafts feature a flat spot in order to ensure a perfect grub screw fit on both the front caster blocks and rear uprights. |

||||

+++ Reinforced C-hubs:The C-hubs of the E4RS III+ are now reinforced to increase their durability. The plastic suspension parts of the E4RS III and III+ are the HARD reinforced versions in order to provide more rigidity and precise control of the suspension movements. |

|

|||

+++ Modified steering blocks:The E4RS III+ features new front steering blocks, that provides an increased steering angle. Since the first E4RS II, the Ackermann has tree positions on the wheel side, for a finer setting, which is exclusive from Team Magic. This parts are higly loaded in graphite. |

|

|||

+++ Zero-Play suspension arms:The E4RS III+ is delivered with new "Zero Play" front and rear arms, of identical dimension than the E4RS III arms. Obviously, these parts feature a high ratio of graphite for a perfect stiffness. The driver can now adjust himself the liberty of movement with an arm reamer. |

||||

Anti-roll bar mounts:For 3 years, the ball-raced anti-roll bar mounts were available as an option part for the E4RS II and E4RS II EVO, via extra holder parts. To minimize the weight, we decided to integrate them directly into the E4RS III and III+ lower bulkheads. It allows the anti-roll bar to work with better precision and efficiency. |

|

|||

Aluminum 7075 spur gear holder:The ultra-light spur gear holder received a hard treatment. |

|

|||

CNC machined Delrin spur gear:Where other brands deliver their 1/10 Touring cars with a simple moulded nylon spur gear, Team Magic includes a Kfactory CNC machined Delrin spur gear ! Two crucial advantages to this:

This is top quality part provided by Team Magic with its E4RS III and III+ kits. |

|

|||

"Low Friction" BANDO belts:Belts provided by Team Magic are now "Low Friction" BANDO models, ensuring an extreme freeness and smoothness of transmission on the E4RS III and III+. Team Magic chose the Japanese leader of the manufacturing of transmission belts, rather than turn to low-cost Chinese suppliers, as to once again to ensure a quality of the highest level. |

||||

Belt tension eccentric adjusters:Team Magic chose to colour their belt tension eccentric adjusters in orange; not to look pretty, but to stand out visually of the black bulkheads and to allow to users to check which tension notch is the eccentric positioned at a quick glance. Orange being the basic colour of the Team Magic logo, the colour contrasting perfectly with black was quickly found. |

||||

Front spool with steel outdrives:The E4RS III and III+ are delivered with a front spool and hard coated steel outdrives. The steel outdrives allows the use the most powerful modified motors without any problems of durability. It is an undeniable advantage for a competition kit. The main part of the spool is machined in hard treated 7075 hard aluminum, for the highest possibly reduction in weight. |

|

|||

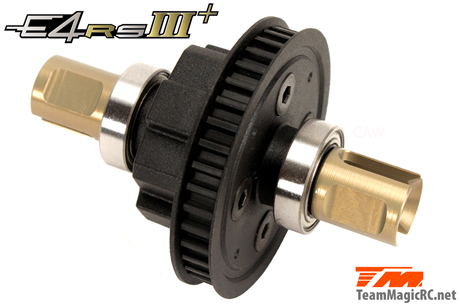

Gear differential with composite gears:The E4RS III and III+’s differential is a reference in gear diffs. Delivered with 4 moulded composite satellite gears, this new ultra compact differential is very light and efficient. The double gasket system ensures the differential’s perfect seal and the diff case is moulded with four unclosed screw holes in order to avoid any negative pressure under them for a greater durability of the screw thread in the main differential case. |

|

|||

Front double-jointed driveshafts:The front driveshafts delivered with the E4RS III and III+ are double-jointed and machined in hard treated steel. The double-joint system allows higher angles of steering and greatly reduce the "chatter" that the front drivetrain generates with standard CVDs. |

|

|||

+++ Rear driveshafts:It seemed necessary to us to simplify the rear driveshafts in terms of the small pin on the inner joint. Indeed, the grub screw sometimes caused problems, contrary to the front double articulated driveshafts. We therefore used the same principle of retaining the pin with a G-clip, which also has the effect of making the articulation more free and constant. |

|

|||

Floating steering system:After 3 years of use of the same steering system on the E4RS II and E4RS II EVO, several drivers wanted work to be done in this area to reduce the effect of the flex. Mounting a double pivot system to the chassis, connected or not to the upper deck, provided a too radical a flex to the front of the car. We had sometimes too much flex without attaching the steering to the upper deck and not enough when we attached it. We also noticed that the area under the steering system attached to the upper deck was a lot more stiffer than the similar area on the rear of the car. To improve it, we decided in a first time to replace the double link with a Y part. This option has improved the flex range, but didn't have the expected influence on the size of the "dead" zone of the chassis under the steering system. In order to solve this problem, we created a floating steering mount for the E4RS III and III+, with central mounting point instead of the two pivots; similar to the floating servo mount that is mounted on the centre of the chassis. |

|

|||

|

|

|||

Optimized steering plate:The position of the steering pivot balls has been modified on the E4RS III and III+ steering plate. As a result, the bumpsteer has been optimized. |

|

|||

+++ Floating servo mount:The E4RS II EVO’s excellent one-piece floating servo has always been an important part of the extreme precision of the car. However, this part was not one of the lightest, and after a few months of test, we choose to reduce the material size for the E4RS III+. |

|

|||

Ultra stiff servo ballcup:Team Magic was the first manufacturer to dare an angled steering servo ballcup on the 3-Belt E4RS, 7 years ago. After so many years of good services, we decided to redraw the servo ballcup in order to make it stiffer and to increase the steering precision over time. |

|

|||

Ultra stiff shock towers:In order to optimize the work of the shock absorbers, we chose to fit the E4RS III and III+ with new ultra stiff shock towers. These towers are made in High Grade 4.0mm Woven Graphite, a guarantee of rigidity and solidity. |

|

|

||

Shock absorbers:The E4RS III and III+'s shock absorbers have been improved, and we created a few new parts:

All this provides a better smoothness of movement, and a wider range of ride height setting. |

|

|||

Low rebound system shock caps:The E4RS III and III+ shock caps feature the new LRS system (Low Rebound System) which minimizes rebound, while keeping a precise and reliable architecture of the shock absorbers. |

|

|||

Teflon coated shock bodies:The E4RS III and III+ shock bodies features a Teflon coating and mirror finish on the internal surface. This provides an unequalled smoothness and quality of movements. |

|

|||

Titanium coated shock shafts:The titanium-coated shock shafts provide an excellent durability as well as a constant free movement. |

||||

Teflon shock pistons:The shock pistons are machined in high quality Teflon to obtain perfectly free suspensions movements. |

|

|||

Shock shaft teflon guides:The small shock piston shaft guides are machined in Teflon. They perfectly complete the new shock bodies in term of smoothness of movement. |

|

|||

Shock spring setting collars:In order to make the ride height setting easier, the shock spring setting collars now features a visual mark. |

|

|||

Shock spring cups:To accept longer shock springs (more than 25mm), we created new aluminum spring cups. This allows to stay in an adequate ride height range (4.5~5.5mm). |

|

|||

Kfactory matched shock springs:The springs provided with the E4RS III and III+’s dampers of are Kfactory matched springs. The #25 springs feature 6.5 coils made with 1.4mm wire, which is a common choice for the rear; while the #27 front springs also feature 6.5 coils, they are made with a 1.5mm wire, which are a perfect complement of the rear springs. This choice of springs provides a good handling on tracks with a medium level of grip. |

||||

Aluminum 7075 wheel hex adapters:The E4RS III and III+’s wheel hex adapters are clamp type and machined in 7075 Aluminum. The clamp type hex adapters avoid any undesirable play around the pin which would could force and restrict the wheel hub at high stresses. |

|

|||

Optimized battery position and mounts:The E4RS III and III+ battery locations have been optimized in comparison to the E4RS II EVO. The central guides are new, and perfectly maintains the battery in place on the center of the chassis. |

|

|||

Quick release battery holder:The E4RS III and III+ also features a quick release battery holder with a Velcro strap. Some say that this system is not good, that it interferes on the chassis flex unlike fiber tape which does not, but after extensive testing we can say that it's exactly the opposite: the Velcro strap perfectly holds the battery in place in its retainers without forcing or over stressing the assembly. This fixation is also a more economical and ecological solution compared to fiber tape. |

|

|||

Battery retainers:The battery retainers allow the battery to maintain perfectly positioned both laterally and longitudinally on the chassis without interfering in the chassis flex as do certain alternative retainers (notably systems with screws on the servo and motor mounts). The retainer plates are machined in High Grade carbon and are adjustable in three longitudinal positions. |

||||

Low Friction ball bearings:The ball bearings delivered with the E4RS III and III+ kits are Low Friction. They are also supplied lubricated with oil, instead of grease, for increased transmission freeness. |

|

|||

Heavy duty body posts:The E4RS III and III+’s body posts are heavy duty with a 6mm diameter. They offer great stability and rigidity of the body fixings. The body height is, of course, adjustable in a precise manner. |

||||

High density foam bumper:The nylon bumper plate is supplemented with a high-density foam with respectable thickness. We thought to reduce the thickness of the foam in order to reduce the weight and the centre of gravity. However, the gain from such a change was negligible compared to the loss of protection in case of crash that we decided to keep the foam at its original thickness as to protect your kit. |

||||

English texts: Lionel Troyon with the kind assistance of Dominique Tranquille. Pictures: Lionel Troyon and Team Magic. |

||||

| Dernière mise à jour le 24/04/2024 Copyrights © code & design: AdaptaWeb | Copyrights © contenu: Team Magic |

||||