|

|

|

|||||

|---|---|---|---|---|---|

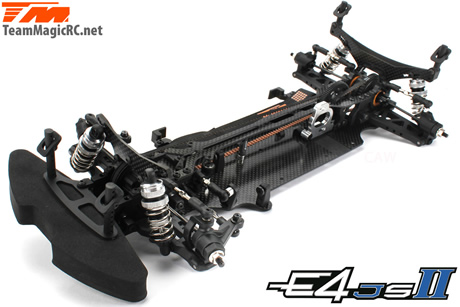

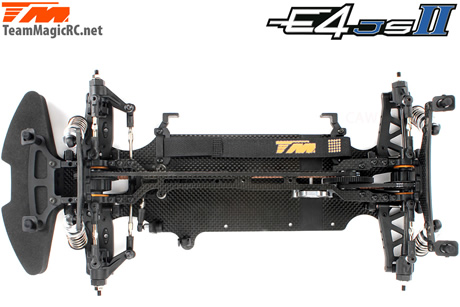

At Team Magic we don't think only to the top competitors, but also about the club racers and casual drivers, who race for pleasure and friendly competition without having to pay out excessive sums to have high quality material nor have to spend hours of maintenance between two days of training. For these drivers, we have created the E4JS II which is based on the ultra performant E4RS II, E4RS II EVO and E4RS III platforms, which have already more that proven their ability in competition. To lower the costs, we did not compromise the quality of the materials, nor the quality of the kit. We opted to reduce the development costs by using what we already had from the E4RS II, E4RS II EVO and E4RS III models, using existing parts such as the E4JR and E4JS shock absorbers and created of a new type of carbon which we called "Eco-Graphite". The new parts (upper and lower bulkheads, centre layshaft mounts, steering bellcrank) are realized in the same "hard" plastic which has already showen its ability on the E4RS II, E4RS II EVO and E4RS III (arms, uprights and steering blocks). |

|||||

The features inherited from the E4RS III:Team Magic utilised numerous elements and parts of the E4RS III to create the E4JS II, which is so in no way a touring car of reduced quality.

Team Magic E4JS II new features:

|

|

||||

|

|

||||

|

|||||

|

|||||

Suspension geometry of the E4RS III:The E4JS II uses the same suspension geometry as the E4RS III. More than that, it are exactly the same elements which are used: Arms, c-hubs and uprights are all directly from the E4RS III, to guarantee a high level of handling and quality. |

Suspension geometry of the E4RS III |

||||

Centred and aligned weight distribution:The E4JS II’s weight centring and distribution is almost identical to that of the E4RS III. The E4JS II benefits from the overall balance of the E4RS III, which has more than proven itself in competition. |

Centred and aligned weight distribution |

||||

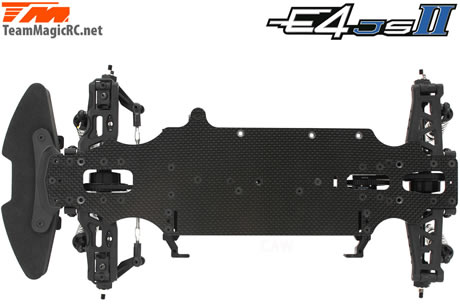

Perfectly symmetric flex:It is difficult not to notice that a non-symmetric chassis inevitably creates a non-symmetric flex. At Team Magic, one of the first elements of the E4RS II specifications was to create a car with the most symmetrical flex possible. One of the features of the Team Magic E4RS II is the symmetric cut of the chassis, including the reaming under the motor, which was also done under the battery pack. This was naturally adapted to the E4JS II, which benefits from the same attention as we carried to the symmetry of the flex as the E4RS III. |

For a perfect flex symmetry the milling under the motor is also under the battery |

||||

New flex points and Flex 3D system (optional):In order to set the flex more precisely, two new flex points have been added just in front of the transmission and on the middle of the car. The 3D Flex system allows to maintain the lateral flex of the car, whilst limiting the longitudinal flex. This is another exclusive innovation by Team Magic for the E4RS III, which can be used on the E4JS II (optional set, reference 507251). |

3D flex system |

||||

New central point of flex New central point of flex |

New rear point of flex |

||||

Narrow 2.3mm ECO-Graphite chassis:A key feature of the E4JS II is the use of our new ECO-Graphite. The High Grade graphite used on the E4RS III is very expensive, both to produce and to machine. To lower the cost and make the E4JS II affordable to all, without using materials with inapropriate flex which would have considerably modified the handling of the car, we created the ECO-Graphite. The E4JS II’s 2.3mm ECO-Graphite chassis has a flex relatively close to the flex found on the E4RS III. |

New ECO-Graphite chassis |

||||

2.0mm ECO-Graphite upper deck:The upper deck is machined in 2.0mm ECO-Graphite and perfectly complements the E4JS II chassis. Together, they offer an excellent compromise for many tracks and surfaces. |

New ECO-Graphite upper deck |

||||

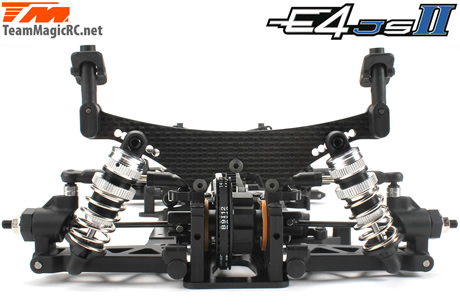

3.0mm ECO-Graphite shock towers:As the chassis and the upper deck, the 3.0mm shocks towers are machined in ECO-Graphite. The many setting holes allow to optimise the position of the shock absorbers in relation to the grip and the configuration of the track. |

New ECO-Graphite shock towers |

||||

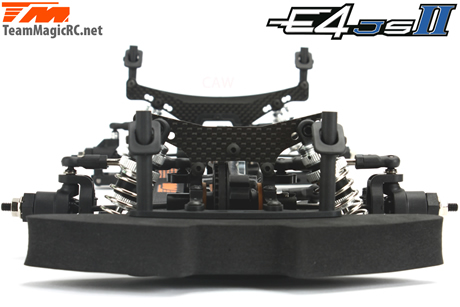

High quality constant volume shock absorbers:The shock absorbers of the E4JS II are classic and standard models by Team Magic. They were previously used on the E4JS, E4JR and E4D models, where they provided completely satisfactory results. |

High quality constant volume shock absorbers |

||||

Matched and optimized shock springs:Rather than simply using existing springs off old models, Team Magic chose to equip its E4RS II with new springs which were especially matched and optimized for a standard use in 1/10 Touring. The front springs are standard springs with 6.4 coils of a 1.5mm thickness, which offer a good front end control. These are accompanied by rear springs with 6.2 coils of 1.4mm thickness which provides a good progressivity and softness for the rear end. This choice of springs provides a good balance to the car and a good handling on tracks with a medium level of grip. |

Matched and optimized shock springs for 1/10 Touring |

||||

Hard plastic lower bulkheads:The lower bulkheads of the E4JS II use very similar shape and design to that of the E4RS II EVO bulkheads. The chosen material is still the hard plastic used for the E4RS II EVO suspension in order to guarantee a high level of rigidity. |

New Hard plastic lower bulkheads |

||||

Hard plastic upper bulkheads:The upper bulkheads of the E4JS II also use same design as the E4RS II EVO counterparts. The chosen material is still the hard plastic, always with the aim of guaranteeing a high level of rigidity. |

New Hard plastic upper bulkheads |

||||

Hard suspension arms, c-hubs and uprights:The suspension arms, c-hubs and uprights provided in the E4JS II kit are the hard ones used on the E4RS III. This to offer to the E4JS II the same rigidity and the same precision in the control of the movements of the suspension which the E4RS III has. |

Hard suspension arms, c-hubs and uprights |

||||

Hard coated suspension shafts:The suspension shafts are hard coated polished steel, in order to ensure perfect alignment and movements without any hard points. The outer shafts feature a flat spot in order to ensure a perfect grub screw fit on both the front caster blocks and rear uprights. The quality of all these parts is the same as the E4RS III. |

Hard coated suspension shafts |

||||

Hard plastic ball raced steering bell crank:The steering system of the E4JS II is also manufactured in hard plastic in order to guarantee a good rigidity of the part. As on the E4RS III, the steering system is mounted with ball bearings on both steering arms and the central link, resulting in an ultra-fast and precise steering movement without any hard points. |

Hard plasic ball raced steering bell crank |

||||

7075 Aluminium motor mount:The motor mount is probably the part which differs the most between the E4RS III and the E4JS II. We wanted to give the possibility for the user to install any type of motor, brushless or brushed. Obviously, it is also possible to install the E4RS III motor mount, as optional part. |

New motor mount compatible with any type of motor |

||||

Hard plastic centre layshaft mounts:The E4JS II has two center layshaft mounts that are also made in hard plastic, in order to offer a good rigidity and durability. They also contribute to guarantee a certain level of flex, necessary to ensure a good handling balance. |

New hard plastic center layshaft mounts |

||||

Aluminium 7075 spur gear holder:The ultra-light spur gear holder is hard treated and directly from the E4RS III. |

The Aluminium 7075 spur gear holder has been optimized |

||||

High Quality 48DP spur gear:The E4JS II uses a standard 48DP spur gear which provides a good level of durability, which is in perfect adequate for the typical use of a RC car like the E4JS II. |

New High Quality spur gear |

||||

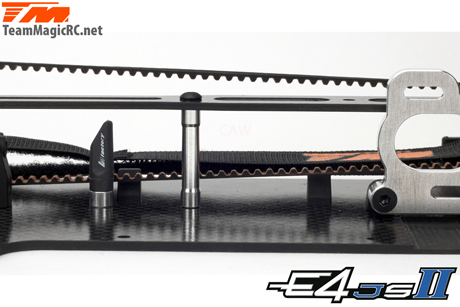

"Low Friction" belts:The belts provided by Team Magic are the "Low Friction" belts used on the E4RS III, ensuring an extreme transmission freeness and smoothness. Team Magic chose a leading Japanese transmission belt manufacturer rather than turn to a low-cost Chinese supplier, as to once again ensure a quality of the highest level. |

"Low Friction" belts |

||||

Belt tension eccentric adjusters:Team Magic chose to colour their belt tension eccentric (origin E4RS III) adjusters in orange; not to look pretty, but to stand out visually in the black bulkheads and to allow to users to check which tension notch is the eccentric positioned with a quick glance. Orange being the basic colour of the Team Magic logo, the colour perfectly contrasts with black. |

The belt tension adjustment excenters |

||||

Gear differential with composite gears:The E4JS II is equipped with the E4RS III gear differential with 4 moulded composite satellite gears. This ultra-compact differential is very light and efficient. The double gasket system ensures the differential is perfectly sealed. The diff case is moulded with four unclosed screw holes in order to avoid any negative pressure under them for a greater durability of the screw thread in the main differential case. |

Gear differential with composite gears |

||||

Steel differential outdrives:The differential outdrives of the E4JS II are machined in steel, in order to ensure an extreme durability. These outdrives also complement perfectly the use of the E4JS II’s new universal driveshafts. |

Steel differential outdrives |

||||

Universal driveshafts:The universal driveshafts were simplified, and features a new retainer clip for the articulation pin, instead of the usual grub screw. We chose to use simple universal driveshafts, provided with a big pin of 3mm instead of the traditional blades of the E4RS III, because the user has be able to drive without having to care of the state of his blades. |

Universal driveshafts |

||||

Quick release battery holder:One of the key features of the E4RS III is its quick release battery holder with a Velcro strap. This element was naturally retained for the E4JS II. Some say that this system is not good, that it interferes on the chassis flex unlike fiber tape which does not, but after extensive testing we can say that it's exactly the opposite: the Velcro strap perfectly holds the battery in place in its retainers without forcing or over stressing the assembly. This fixation is also a more economical and ecological solution compared to fiber tape. |

Quick release battery holder |

||||

Low Friction ball bearings:The kit is delivered with the E4RS III Low Friction ball bearings. They are also supplied lubricated with oil, instead of grease, for increased transmission freeness. |

Low Friction ball bearings |

||||

Ultra free pivot balls and ball cups with minimized play:The ultra-free pivot balls and ball cups with extreme low play from the E4RS III are used on the E4JS II, in order to offer the same freeness of movements of the suspension and facilitate setup on the E4RS III. |

Ultra free pivot balls and ball cups with minimized play |

||||

Heavy duty body posts:The body posts are heavy duty with a 6mm diameter from the E4RS III. They offer great stability and rigidity of the body fixings. The body height is, of course, adjustable in a precise manner. |

Heavy duty body posts |

||||

High density foam bumper:The nylon bumper plate is accompanied by a high-density foam with respectable thickness. All these parts are from the E4RS III. |

Nylon front bumper |

High density foam bumper |

|||

English texts: Lionel Troyon with the kind assistance of Dominique Tranquille. Pictures: Lionel Troyon and Team Magic. |

|||||

| Last update 24/04/2024 Copyrights © code & design: AdaptaWeb | Copyrights © contents: Team Magic |

|||||